Power Factor Correction Capacitors

Sunny Capacitors offer reliable and Hyper Heavy Duty Technology innovative products and solutions in the fields of Reactive Power Compensation, Power Quality Energy Management to customers worldwide.

The founders and key personnel have over 40 years of consolidated international experience in design, development and manufacturing of Power Factor Capacitors, Harmonic Filters reactors, Power Factor Correction Equipment, Measuring devices and Energy Management Systems. Our innovative products are designed and built on sound engineering principles with total quality and customer satisfaction as a guiding rule. We are committed to delivering a positive value to each and every client, backed by our dedication to the highest standards of client satisfaction, reliability and integrity. All our products are manufactured to the highest prevailing international standards & the manufacturing locations are certified according to ISO 9001-2015

Certificate:- BIS CE Marking ISO 9001-2015

HIGH PERFORMANCE CAPACITORS The Hyper Heavy Duty Capacitor (HHDC) type Power Capacitor represents reliable and optimized Solution for Power Factor Correction. The output of these capacitors ranges from 0.5 kVAr to 50 kVAr. The HHDC series is a 3 Phase integrated capacitor design particularly made for Power Factor Correction in Commercial & Industrial applications. These Capacitors feature the use of a unique Metalized Polypropylene film as the dielectric to ensure a long working life with low losses.

The HHDC series are Self healing Capacitors, where the Electrode layer which is a special metal alloy is vacuum deposited on to the Polypropylene film dielectric. The 3 Phase Capacitor is internally composed of 3 Single Phase Capacitor windings assembled in an optimized geometric design. The electrode of the capacitor i.e., the special Metal alloy layer is connected in parallel using a special purpose Metal Spraying technology. This special process combined with the design of the electrode enables the capacitor to have high peak current withstand levels. The Capacitor elements are processed under high vacuum to eliminate all moisture as well as to impart the correct level of thermal stability. This is an extremely critical process by which oxidation and partial discharges can be avoided during the working life of the capacitor and thus ensure better capacitance stability. The Capacitor elements are encapsulated in a special purpose synthetic material which ensures better dimensional stability and thermal conduction of heat from the insides of the capacitor.

The entire capacitor assembly is housed in a extruded cylindrical aluminum case and sealed with a special double seaming technology The HDDC Capacitor technology features a triple safety system i.e., Self healing – this is a process by which the Capacitor restores itself in the event of a fault in the dielectric which can happen during high overloads, voltage transients etc., Pressure sensitive disconnector – this is provided in each phase of the capacitor and enables safe disconnection and electrical isolation at the end of the life of the capacitor & Finger Proof Assembly of Cover All Cylindrical Capacitor are seamed with high end technology Faculty that makes Capacitor Leak Proof and also our Capacitor manufactured with burst proof mechanism that protect other Panel Components Getting damaged in case of Capacitor Failure and Punctured it's on the Spot. The HHDC Capacitor features the use of a highly reliable two way termination design involving the use of copper and brass terminal clamps. In addition the clamping screws that are used are of large Size to ensure proper torque application on the connecting cable.

This terminal design has therefore a very long and reliable performance capability in comparison to conventional termination technologies. Discharge resistor modules are available in a completely integrated design which can be easily fitted on to the capacitor. The terminal of the capacitor also enables multiple capacitor units to be banked within its permissible current carrying capacity. The HHDC series is therefore an optimal combination of high technology and ergonomic design which offers to the customer.

What is Power Factor

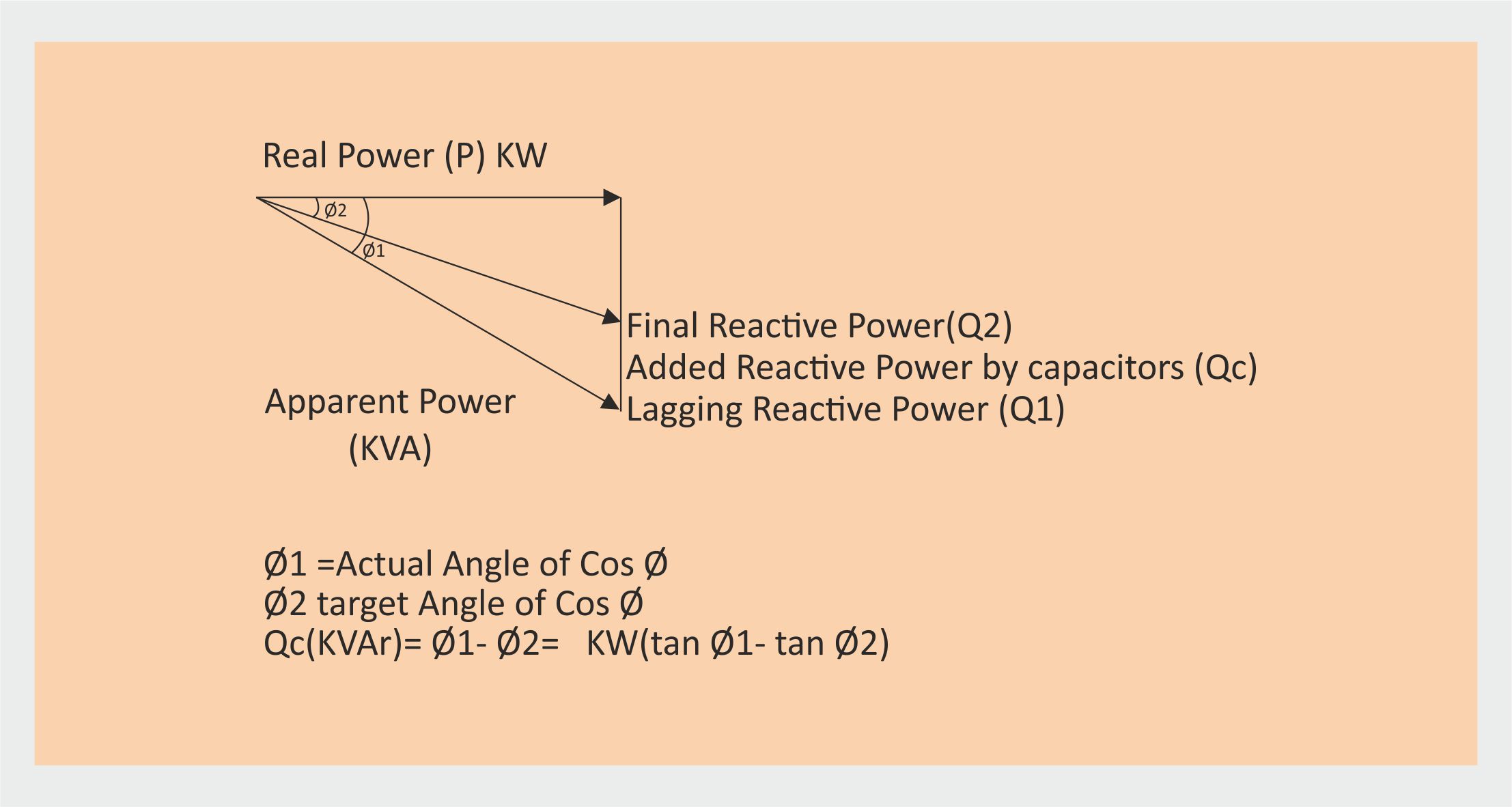

Power factor (PF) is the ratio of working power, measured in kilowatts (kW), to apparent power, measured in kilovolt amperes (kVA). Apparent power, also known as demand, is the measure of the amount of power used to run machinery and equipment during a certain period. It is found by multiplying (kVA = V x A). The result is expressed as kVA units. Real Power (kW) is the power that actually powers the equipment and performs useful, productive work. It is also called Actual Power, Active Power or Working Power. Reactive Power (kVAr) is the power required by some equipment (eg. transformers & motors) to produce a magnetic field to enable real work to be done. It's necessary to energise this equipment however it does not perform any productive work.

Apparent Power (kVA) is the vector sum of Real Power (kW) and Reactive Power (kVAR) and is the total power supplied through the mains that is required to produce the required amount of Real Power for the The ideal power factor is unity, or one (1.0) which means that all the energy supplied by the source is consumed by the load. Anything less than one means that extra power is required to achieve the actual task at hand. Power factors are usually stated as "leading" or "lagging" to show the sign of the phase angle. Capacitive loads are leading (current leads voltage), and inductive loads are lagging (current lags voltage).

Advantages of power factor corrections:

Reduction of reactive power in system Low cost of energy levied at better pf Improved voltage quality Reduced voltage drops Optimum cable design Reduced transmission losses How to calculate power factorTo calculate power factor, you need a power quality analyzer or power analyzer that measures both working power (kW) and apparent power (kVA), and to calculate the ratio of kW/kVA.

Cautions:

1. The use of Capacitors in Electrical networks with Harmonic presence can result in overloads on the capacitor which are beyond the permissible levels. In addition there could also be the risk of resonance type effects which can cause amplification of electrical parameters. Consequently, care must be taken during the process of selecting and using capacitors in such networks as it may be necessary to install Reactor protected capacitor lines or Harmonic filters.

If you have any questions regarding our services, please contact us or call at 8928901275.